Selecting Countertops for Your Kitchen or Bathroom

Full slabs at a slab yard.

When it comes to designing a Kitchen or Bathroom, I look at selecting materials a bit like a jigsaw puzzle- you need all of the pieces to come together to get the final picture. At the start of every design project, the materials I focus on first are cabinets, countertop, backsplash, and floor. But the design always seems to fall into place once you select the material for the countertop. Picking a countertop is usually a falling-in-love sort of thing. After narrowing down the type of material that best suits your home and finalizing the overall feel for the design, it’s time to go out shopping and look at options in person. This is best done with an interior designer (or really good sales associate) who can point you in the right direction so you can just pick the one that speaks to you. Once you find that perfect material, the rest of the design puzzle comes together fairly easily.

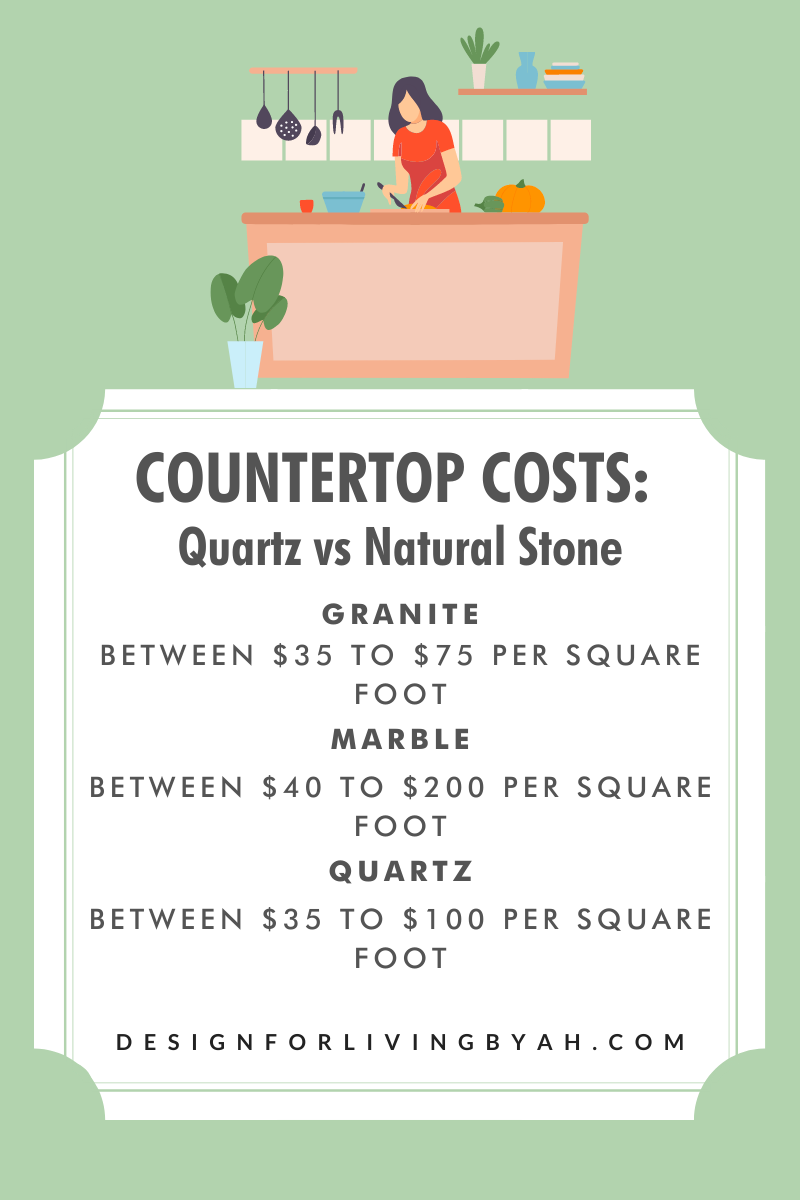

Countertop selection is one of the most important decisions you make in designing your home. Are you willing to sacrifice durability for beauty? Sacrifice beauty for cost? Want all three? Well then, you’re going to spend a pretty penny. See below for my overview on the different types of materials available and some factors that contribute to both durability and cost:

An absolute black granite island countertop contrasts a veined white quartz perimeter with a self-splash.

A little general information on countertop materials:

High-end countertops (also referred to as “solid surfaces”) are sold by the slab. Slabs are large, heavy, pieces that have to be specially cut and installed (referred to as fabrication). Countertop fabricators are a completely different team than the contractor because it is so specialized. Once the slabs are purchased, they are delivered to the fabricator. Then after the cabinets are installed, the fabricator comes out to the home to do a measure and template. Once completed, they go back to their shop and tape the layout onto the slabs. If the slabs aren’t uniform and have a lot of unique movement (like natural stone or some quartz slabs) then the designer and client will want to approve the layout before the pieces are cut to ensure the movement of the material works with the design. Once the layout is finalized, the slabs are cut to size. They are then brought to the job site and installed.

Types of Countertop Materials

Let’s start with the two main categories: natural stone vs engineered (man-made)

Natural Stone

Natural stone includes granite, marble, quartzite, and soapstone. These are quarried materials, meaning they are cut from the earth. Every natural stone slab is completely unique. Depending on when and where it is quarried from, even the same type of material can have a huge amount of variation. Natural stone needs to be sealed every 6 to 12 months, but it is a pretty simple process that the homeowner can do themselves.

Granite

Granite was the first commonly used natural stone solid surface. Granite became extremely popular in high-end homes and remodels during the 1970s because of its natural characteristics, color options, and durability. There is a huge range in both cost and appearance. Lower priced granites are more ubiquitous, often referred to as builder-grade. Higher-priced granite can have incredibly unique characteristics and colors and is considered a luxury product.

Ideal use for granite: Kitchens, Bathrooms, Fireplace- pretty much anywhere!

See granite countertops here.

Marble

Marble is a classic material that has been around for centuries and is associated with luxury. It is the only natural stone countertop material that comes in a clean white. Because marble is soft and porous, it can be prone to etching and staining. For this reason, I generally avoid using marble for Kitchen countertops and often even the Bathroom (but rules are made to be broken!).

Love the look of marble but don’t want something more durable? Some quartz and porcelain panels look incredibly realistic!

Ideal use for marble: Fireplace and decorative areas (spaces where the stone is less likely to be etched or stained)

See marble countertops here.

Quartzite

Quartzite is currently my favorite natural stone and is definitely having its day. It is one of the more expensive options because of its natural beauty and durability. Additionally, it is more difficult to fabricate so the cost to cut can be higher than granite or quartz. It can also damage easily during fabrication, which means you might have to buy an additional slab. But boy is it pretty!

Ideal use for quartzite: Kitchens and Bathrooms- my favorite is on a Kitchen island as a contrast to the perimeter. The unique movement makes for an incredible focal point!

See quartzite countertops here.

Gabana quartzite slab from Cosentino in Roseville.

Image of the same Gabana quartzite installed in a Kitchen. Click here for more images of the completed project.

Soapstone

Architectural soapstone is dense and non porous as well as chemically inert (meaning it won’t be damaged by lemon and cleaners like most natural stone options). It is prone to scratches and knicks and meant to show its marks (almost like a butcher block countertop).

See soapstone countertops here.

Factors that affect cost

Some factors that contribute to cost: where the natural material comes from, current popularity (more popular material runs out of stock quickly and since it’s a natural material you can’t just “make” more of it), how pure the material is (does it have fissures and fillers? Check the back of the slab), thickness (common thicknesses are 2cm or 3cm), size of the slab (slabs are priced by the square foot so smaller slabs are less expensive), fabrication difficulty (quartzite is more difficult to fabricate than granite, different edge details increase the fabrications cost).

countertop tips:

For rare or delicate materials, reserve an extra slab in case one is broken or damaged during transport, fabrication or installation

If the slabs are all unique or have a lot of movement, approve the layout before the material is cut

Reserve sequential slabs from the same batch whenever possible

Want your countertop to be completely uniform and consistent? Go with a man-made material

Communicate with your fabricator to ensure you aren’t wasting too much material

Many materials come in different finishes: polished is the most common, but honed and leathered options are currently very on trend and can be a nice change or contrast to the glossy surface. Depending on the material (and sometimes even who you ask), different finishes can be slightly more or less prone to etching depending on the material.

Engineered Material

Quartz

Quartz is the material we were all waiting for. The name is a bit confusing because there is actual quartz (like the crystals used in healing) and quartzite (the natural stone that I’m in love with) that are different from engineered quartz. Engineered quartz countertops are a combination of natural quartz, polymers and fillers. They are highly resistant to heat, etching and scratching, making them one of the most durable solid surface options for kitchens and bathrooms. They are also considered low maintenance because unlike natural stone, they do not require sealing.

There is a huge variance in the cost of quartz, which can be attributed to the ratio of natural quartz to fillers, where it is fabricated (some are made in the US, some overseas), import tariffs, etc. Like everything else in life- you get what you pay for. High quality, American made quartz is significantly more expensive than options fabricated overseas. Lower end quartz can crumble during fabrication and scratch more easily because of the amount of filler.

Common brands: Silestone, Cambria, Ceasarstone

Quartz countertops with a 4” thick mitered edge detail. View the full project here.

Ultracompact Countertop

Ultracompact Countertops are incredibly durable (you can take a blow torch, sharpie, or steel wool to the surface) and one of the only solid surface materials that is warrantied for both indoor and outdoor use. The slabs are slightly smaller than most solid surface slabs and it requires a special blade and licensed fabricator, which make it on the more expensive side.

Common brands: Dekton, Neolith

Porcelain Panels

A new option that is emerging are porcelain panels. They are the size of slabs but generally thinner and come in a huge variety of options, including sought-after marble and quartzite looks that are incredibly beautiful. They require a specially trained fabricator to cut and install. I’ve only ever used them on shower walls in Bathrooms (if you hate grout they are a great option!), but I have been told they can be used for countertops in the Kitchen as well.

Common Brands: Magnifica, Stonepeak

Magnifica brand porcelain panel shower walls and bench seat. View the full project here.

Laminate

Laminate countertops are the most affordable of the solid surface options. They are non-porous but because they are made of plastic, particle board and/or kraft paper they are easily scratched and sensitive to heat.

Common brands: Corian, Formica

Additional options to consider include slab thickness and edge detail. Overwhelming? That’s what your interior designer, contractor, sales rep and fabricator are for. Surround yourself with good people and they will guide you through the process.

My favorite resources for solid surface materials in the Sacramento Area: Arizona Tile, Cosentino, and Bedrosians.

Once you have your main materials selected, lighting and hardware are the finishing touches. They are the accessories. The jewelry. Do you want to dress everything up and make a statement, or keep it simple and let the rest of the outfit be the focal point? Finalize your countertop material first and you will have a better vision for the end result, which will make selecting accessories much easier.

Disclaimer: All of the above information is the insight and opinion of Design for Living. Costs and details should be confirmed.

Countertop Process

1. Narrow down the type of material that best suits your space (want something durable? eliminate marble and laminate).

2. Have a good idea for you footprint so you know approximately how many slabs you require (this might vary depending on the size of the slabs, but you can go with an average size of 60 x 150” to get a count before you go shopping).

3. Look at installation images of different types of countertops to get a feel for what you styles like and don’t like.

4. Time to shop! Bring along your floor plan and any design materials you already have selected or that you’re considering so you can look at them with the slabs.

5. Once you’ve selected your material, put it on hold and give the final details to your contractor and/or fabricator to confirm the slab count. Sometimes the client will do the purchasing, other times the designer, contractor or the fabricator.

6. Usually around the time the cabinets are being installed the slab vendor will deliver the material to the fabricator.

7. After the cabinets are set, the fabricator will come out to template the cabinets. This is when they look at cutout details like the sink and cooktop so you might need to have these items present at the time of the template. Check with them to confirm!

8. Does your material have a lot of movement? If so, you should approve the template to ensure you’re happy with how everything looks. Some people like to emphasize the veining or color variation, other times people want it to be as consistent as possible. Don’t leave it up to the fabricator if you have a preference!

9. Once the layout is confirmed, the fabricator will cut the slabs and apply the edge detail in their shop.

10. Finally the installation! Plywood is laid first to build up the height and the countertops are glued to the plywood. Holes are drilled for the faucets and air switches. Undermount sinks are installed at this time because they are locked under the countertop.